EA is a multi-lingual, cloud-based application and data base of engine, vehicle and fleet operational data to help fleet operators improve their business processes from data analysis and asset-specific models to predict risk associated with operational decisions.

Some basic concepts are:

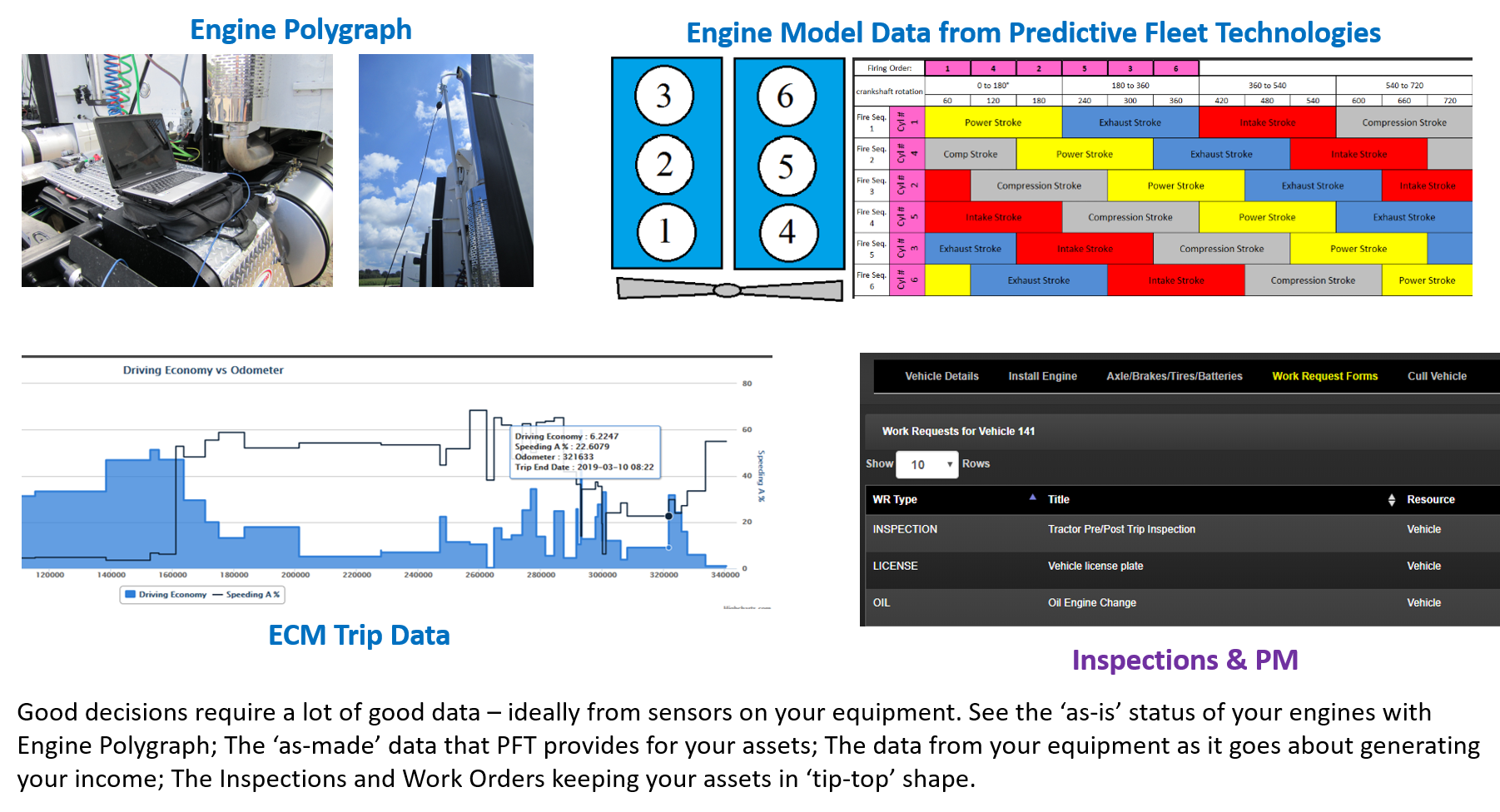

PFT provides data that is publicly available on engines, vehicles, time zones, geography, units of measure, regulations, etc., relieving you of redundant data entry. Likewise, we provide interfaces to data sources of your vehicle/engine trip reports, engine oil test results, exhaust gas analysis, telematics on-road data. We can interface to your Dispatch, PM, inspections and repair work order systems.

Alerts are directed to people in roles related to the topic of the alert.

The data gathering and processing steps are performed in parallel ‘layers’ outlined here:

- Users with EA Admin authorization maintain ‘global data’, translations, many edit tables, and standard text content.

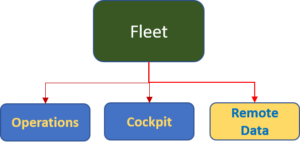

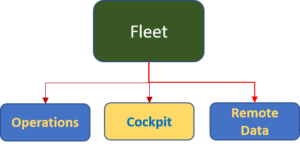

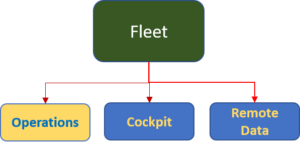

- Users with Cockpit authorization can maintain their fleet’s asset data and personnel assignments, alert trigger values and routing, Parts standard costs, Work Order Templates, .

- Users with Operations authorizations can update their fleet’s asset usage data, inspections, work order activity, parts & fluids inventory and usage.

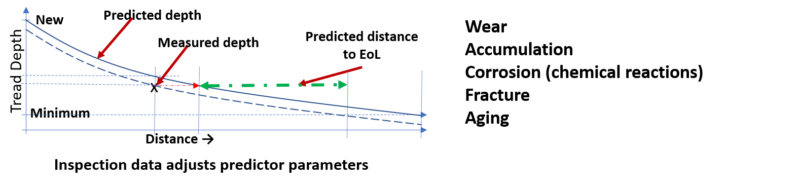

- Remote Applications provide data on engine and vehicle usage, data from periodic testing (EP, ECM trip data (only DD engines now), Emissions test results, 5-Gas (Exhaust) Analyzer, Coolant Pressure results, Starter Current Draw, Engine Oil test results)

- Diagnostic models are based on Rules that list expected observation thresholds of key data values based on an assumed issue. The thresholds are associated with asset ‘vocation’. These ‘abnormal observations’ are compared with actual data to propose a Cause for the issue and a suggestion to remedy the problem.

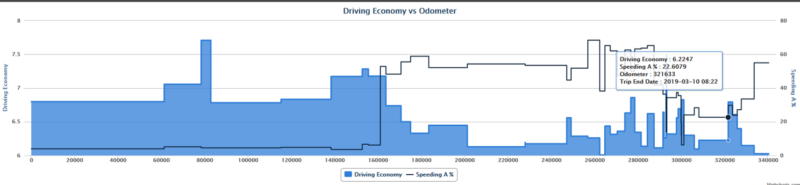

- Planned Predictive Models use past history of activity (hours running per day, external conditions, operator behavior, component condition, etc.) and physical deterioration models calibrated by Fleet history to predict future utilization and consequent deterioration resulting is an End-of-Life (EoL) date calculation. These are based on the ‘vocation’ assigned to each asset.

The following example data flow illustrates how the pieces fit together:

- The Remote layer gets information from fleet operations that an Event has occurred – a trip has completed and the trip data sent to the servers.

- Key data elements are extracted and bundled to update data about the affected assets.

- Affected assets might be connected to components with their own status and predictive models. The connections are provided by ‘maps’ associated with the asset chassis.

- Any of those components can be further connected to more detailed components. E.g., axles have bearings, brakes, and tires (which depend on axle type – steer, drive, trailer, lift)

As the data flows through the network, it triggers the wear predictors to generate new predictions based on the experience of the event (trip, in this case).

Periodically, forecasts of future usage of the asset are combined with the predicted wear rates to generate the latest End-of-Life (EoL) dates to be used in sending alerts and Work Order, as appropriate.

The predictor graph shown below illustrates how the tire-specific wear prediction gets updated by inspection data and the new wear value gets projected to its EUL (End of Useful Life) distance. The forecasted usage can then convert that distance to its EoL date.